In this video, you’ll see the entire build process unfold inside SailGP’s composite workshop — from raw carbon fibre sheets to precision-engineered parts ready for the racecourse. It’s a rare, detailed look at the craftsmanship and technology driving the F50’s blistering performance.

It begins with something that looks impossibly fragile: a paper-thin sheet of carbon fibre. Flexible, almost weightless in your hands, it’s hard to believe this is the raw ingredient for one of the fastest sailboats on the planet — the SailGP F50.

The F50 is a foiling catamaran capable of speeds over 50 knots. Its secret weapon is carbon fibre — the same material that powers Formula 1 cars, high-performance bicycles, and aerospace engineering. But in SailGP, the stakes are different. Every gram saved can mean another fraction of a knot gained, and every component must withstand brutal loads, race after race.

Laying the foundation

Carbon fibre starts as tightly packed carbon atoms arranged in a crystalline lattice. It’s often supplied as pre-impregnated fabric (prepreg), where each fibre bundle is already coated in resin. This means the resin will only cure when the part is heated, giving technicians more working time.

The journey begins with a mould — the exact shape of the part to be made. Technicians work to engineering drawings that specify the number of layers, the type of carbon fibre, and the angle of each layer. These angles matter: by orienting the fibres differently, the part gains strength in multiple directions, crucial for the complex loads of high-speed foiling.

Each sheet is cut by hand and carefully placed. In one example, a part might require eleven layers — the first for shape, the last six for reinforcement in high-load zones. Measurements on the mould show where extra carbon patches will go.

Locking it together

Once the lay-up is complete, the part is sealed inside a vacuum bag. A perforated film and a mesh layer allow air to escape without the bag sticking to the carbon. As the vacuum pump runs, the pressure pulls the carbon tightly against the mould, consolidating the layers and eliminating voids.

Before curing, the part undergoes NDT scanning (Non-Destructive Testing) to ensure there are no defects hidden between layers. If it passes, it heads to the oven. Inside, controlled heat transforms the soft, flexible lay-up into a rigid, high-strength composite.

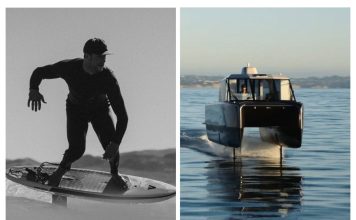

A new era for foils

In 2024–2025, one of the most significant upgrades to the F50’s carbon arsenal arrived — new titanium and carbon fibre T-foils. Built by Strata Manufacturing, with carbon-fibre wing tips engineered by Armstrong Foils, these are designed to reduce drag, improve stability, and increase top-end speed. The carbon tips are detachable, a safety measure to limit damage in a collision, while their precision shape helps keep the boat flying higher and faster.

From shop floor to racecourse

Once cured, parts move to the fit-out area. Here, internal structures such as bulkheads, cockpit floors, and foil cases are bonded into place. High-load zones — like where the foil case meets the hull — are reinforced with extra carbon laminates, vacuum-bagged to pull resin through and ensure perfect adhesion.

A thin protective coating is then applied to seal the carbon from moisture. Once the deck is bonded on, technicians install steering systems, hydraulic controls, electronics, and team branding. At this point, the once-floppy sheet of carbon fibre has become part of a lethal, precision-engineered F50.

The heartbeat of SailGP performance

In SailGP, carbon fibre isn’t just a material — it’s the foundation of the sport’s speed and spectacle. From the foil tips that slice through the water to the wing sail towering above the deck, its strength-to-weight ratio makes the F50 possible. And with suppliers like Strata Manufacturing and Armstrong Foils pushing new designs into the fleet, the evolution is far from over.

Every time an F50 lifts onto its foils, skimming above the surface at highway speeds, it’s the product of thousands of hours of meticulous cutting, layering, curing, and finishing. The journey from paper-thin sheet to race-ready weapon may be hidden behind glossy paint and sponsor logos — but it’s the heartbeat of SailGP performance.